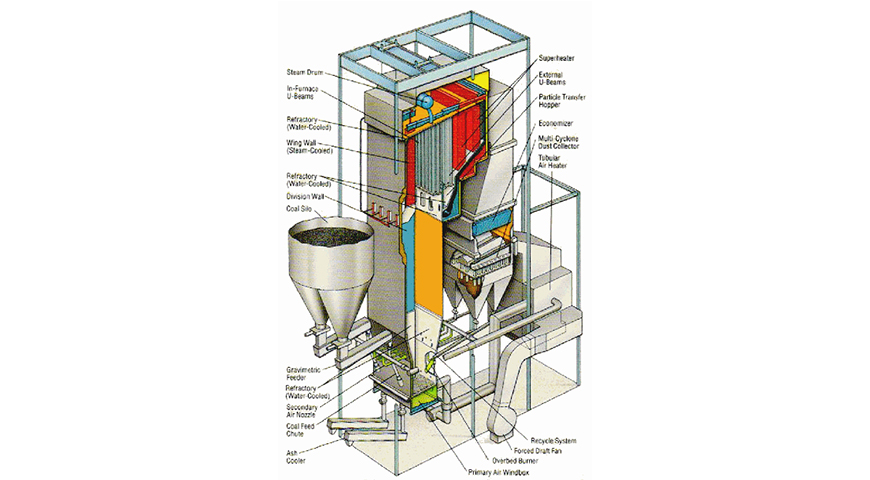

Circulating Fluidized Bed Combustion (CFBC):

CFBC technology has evolved from conventional bubbling bed combustion as a means to overcome some of the drawbacks associated with conventional bubbling bed combustion. This CFBC technology utilises the fluidised bed principle in which crushed (6–12 mm size) fuel and limestone are injected into the furnace or combustor. The particles are suspended in a stream of upwardly flowing air (60-70% of the total air), which enters the bottom of the furnace through air distribution nozzles.

The fluidising velocity in circulating beds ranges from 3.7 to 9 m/sec. The balance of combustion air is admitted above the bottom of the furnace as secondary air. The combustion takes place at 840-900 °C and the fine particles (450 microns) are elutriated out of the furnace with flue gas velocity of 4–6 m/s. The particles are then collected by the solids separators and circulated back into the furnace. Solid recycle is about 50 to 100 kg per kg of fuel burnt.

The technical standard’s and particle measurement distribution of the material is predetermined for practicality as good as economic system of the product on the foundation of technical requirement with specified fuel and boiler design.

PERFORMANCE

EXTRA FEATURES

For manufacturing and offering a qualitative range of products, we have developed a state-of-the-art infrastructure facility. Our world-class facility is well-equipped with the latest machinery and advance technologies that helps us in carrying out all the business operations without any hassle.